Doctors of Running Sustainability Project, Volume 2

By Bach Pham, Content Manager

In our second edition of the Doctors of Running Sustainability Project, we spoke with Hylo Athletics about their unique take on tackling sustainability from a production and end-of-life standpoint. Based in the UK, the company was founded by former footballer Michael Doughty. Michael sought to make a brand that aligned with his desire to curb the environmental impact of footwear in today's marketplace. In our interview, we discuss exactly how he aims to do this with Hylo's aggressive take on design and afterlife process.

About the Doctors of Running Sustainability Project

In this long term series, we'll be talking with companies, researchers, and forward-thinkers on the subject of footwear sustainability. In 2019, it was found that over two billion running shoes were purchased in the calendar year. With running shoes as popular as ever, they bring a unique problem as far as waste is concerned. While clothing tends to have ways to breath new life through repair and reuse, footwear currently has a fairly definitive end-of-life. Sustainability, however, has quickly become the focus of footwear brands in the past two years as more and more new materials and technology have entered the market in an effort to tackle the issue.

Editor's Note

This discussion was not a sponsored piece with Hylo. We appreciate Michael and his team at Hylo for their time and willingness to talk about product and challenges with us.

Interview with Michael Doughty, Co-Founder of Hylo Athletics

"We want to focus on the impact of our product and ask "is that impact better than what's out there" and if we can make that impact better and improve it. "

It is interesting to think about the impact of joining a brand and all the principles that go with that decision.

Every time we make a purchasing decision, we take a world we want to see. We have a lot of respect for that decision. The consumer has a lot of power. Every time you wear a t-shirt, that t-shirt is an embodiment of you, your values and what you think. That's particularly prevalent in sportswear whereby there's this emotional connection to sports brands, athletes, etc, and what you are putting on your chest is a representation of yourself, more-so than any other space in my opinion. That is actually an amazing opportunity to change the way people think about problems, issues, and to inspire people to be the best version of themselves. That's why I love sports and sports brands: they really change the way people think.

The first conversation we ever had about the idea - Hylo wasn't a name or even a thing at that point - was in February 2019, which was about three years ago now. We spent 18 months getting a product to what it is today in front of you. The brand and the name and just, really trying to pin down what the values, what are the pillars we want to be as a company. Then we launched in terms of sale in September of 2020, right in the midst of everything that has been. We launched during a challenging time. We've grown since, but we've been more importantly been learning since how to improve and optimize our product and ultimately, the service for the people who support us and the athletes.

That's an extremely fast amount of time really to go from zero to sixty to have a product and a brand. I'm sure it didn't feel that - maybe it did - but it's an impressive turnaround.

From a product perspective, it sounds a little cheesy or a bit of a cop-out, but I was just focused on a product that performed for the athlete. Because obviously no one wants a product that doesn't work, doesn't feel good, doesn't feel comfortable. But also a product that was better from an environmental point of view. From conversations around sustainability in every sector now, it's about how we define what is good, better, and different. We don't want to take the conversation towards perfectionism. It doesn't exist. We don't want to take the conversation towards sustainability. We want to focus on the impact of our product and ask is that impact better than what's out there and if we can make that impact better and improve it. For us, it's not about having a binary discussion of "we're the best, we're team sustainable." We want to make shoes in a better way, we want to drive environmental improvement in footwear and sportswear. That starts with a bit of humility and a bit of not sort of BS.

It's also heavily iterated and constantly changing. Our first version of the product, we learned so much. We are almost, like, ninth iteration which is captured as Run 2. What you have before you is a comfortable neutral runner that's super lightweight and has great versatility for different types of use, but can also be made better which is always part of our focus. That's always our focus, how do we learn from our customers and how do we continue to innovate.

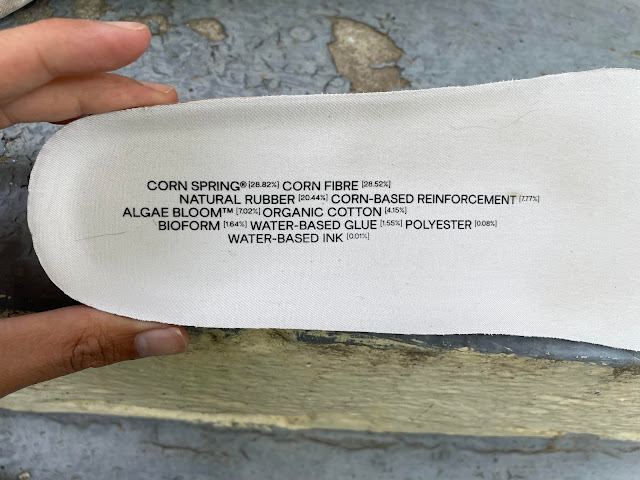

So when we look at that problem and what petroleum derived materials and the challenges they pose and the end-of-life issues they pose, we wanted to try and find bio-alternatives. Essentially bio-synthetics that are derived from nature that are regenerative, that can be replenished. That also at end-of-life don't cause the same biodegrading issues as synthetics. We wanted to try and mimic the same level of performance, but with a different environmental impact. There is a reason why shoes are made in certain ways and yes that can be improved and yes there is development to happen there. But we're not trying to reconstruct the architecture of a shoe because feet are feet right. We are trying to change the materials that shoe is made with that meet the performance requirements for the customer and for us as a brand. That's our sort of focus and continues to be our focus: how do we improve the bio-content of the shoe, how do we improve the recycling capabilities and the quantity of customer take up in the program, how do we reduce our carbon impact. How do we across the value chain of our whole production, improve our impact?

"The models of current consumption can't continue to happen. We're consuming too much and they are not lasting long enough. All it leads is to more and more impact."

Our initial feedback was that people wanted heel support and they want more durability around the midfoot area and more support. We had to find material solutions to that, to essentially correct that. What you see in front of you is the ninth or tenth iteration of tweaking aspects of the pattern. The first version had a super wide toebox which some people loved, but some people found too wide so the sizing was difficult so we had to find a middle ground on the pattern engineering. The original lacing system only had seven eyelets on the top. This one has eight to allow you to do a runner's lock which locks your ankle in and gives you more security in the heel. Those aspects are little tweaks we made but fundamentally changed the engineering. The first one was super lightweight, but missing those components that our feedback helped identify. Without that we wouldn't have a product. As we look forward, the next challenge for us is the midsole. How we improve the bio content in the midsole and cushioning. Midsoles tend to be environmentally the worst in terms of production. We're working on some exciting development at the moment. Also the heel area: all shoes will be made with foam around the heel area and tongue, alongside the midsole is invariably petroleum-derived and very difficult environmentally, both from an end-of-life perspective and from a chemical/carbon perspective. But the foam gives the customer the comfort and margin for error in terms of fit. That foam package gives you a fit in your size or a half size up if you need which offers options.

We can't just put foam into the shoe like everyone else because it doesn't fit our environmental mandate, so we've been working on a very exciting solution to that which mimics the performance of foam without the environmental difficulty for it. It's not a silver bullet: no development is ever finished, no material is perfect environmentally either, but what you see I'm super proud of.

Our reviews and general feedback from customers is that it is a very comfortable, very wearable shoe. Because of its aesthetic, it's been deemed to be versatile which is an important part of sustainability as well. How many use cases can you get out of your product, so you don't need ten different products. You can have or two that really serve you in different ways. What we landed on is something that captures that.

The story behind that is that footwear is a linear model. There's high usage that goes through these products and limited lifespans. Most of the time they go to the customer, the customer uses them and they have no real secondary use. That starts at the beginning of the design and production process. We wanted to have accountability and traceability as a core focus. Each of our colorways are numbered in a specific way so that when the customer reaches out to us, I have number xyz within what I currently own, we can pinpoint the production date, the factory in which it was made. It helps us at end of life talk to third parties who are going to support our recycling to say this is how this product and the material composition. When you are a highly iterative company, every time you run a production line you might tweak something which will slightly alter the balance of things. It's really important that you can pinpoint each product and what goes into it.

You hit the nail in the head. It's quite a linear process at the moment. Factories and brands make shoes, customer buys them and uses them for high performance usage - especially athletes. Tons of force and energy are exerted on the product and invariably durability and performance on this very fine axis in balance. If you were to make a bulletproof shoe, the performance would completely drop off a cliff right? You might see a lot of performance, but not a lot of durability then sometimes. Why should a customer have to run slower too though, and change the way they perform in order to make the product last. It's the responsibility of the company to create products in a different way or business models in a different way. What you touched on is accurate: at the moment loads of shoes end up in landfills, loads of shoes are end-of-life with no solutions. What we wanted to do without a clear solution at launch was to create a recycling program where we would take responsibility for our products. My belief system is that brands and companies can't just make a product and send it to the customer and it's up to the customer; we need to make sure we are responsible for its journey from beginning to end.

So we've essentially been collecting and trying to incentivize with our customers store credit on Hylo's dime and paying for the shipping of the products back so we can help create new solutions and new value change when they are old. That is a key problem: for an old shoe what is the value proposition there? Companies don't care about that, because what are they going to with it? Also, without customer buy-in and volume, there's no recycling output you can generate really. What we are trying to do essentially is rethink what we do with old products. Can we think of them as new products? Can we work on customer behavior so that you don't see it as an old shoe, but a gateway to a new shoe.

With us, we are storing our product in our warehouses to reach a critical mass. We have been working on proof-of-concept [exercise on whether a concept can be turned into a functional, practical reality] with a third party company who we are in partnership up with to grind up the shoes and turn that into hopefully new materials for us to use in our future products. It's highly iterative and we're on a big journey and we need customers to buy-in. The models of current consumption can't continue to happen. We're consuming too much and they are not lasting long enough. All it leads is to more and more impact.

What is a B-Corporation Certification?

Recently, Hylo received the designation of being a B-Corp. This certification is for for-profit companies for their social and environmental practices, the B referring to "Benefit." The certification identifies that the company is meeting social sustainable and environmental practice standards, along with providing transparency about their practices with the public. Other brands with a B-Corp includes All-Birds, Ben and Jerrys, and Patagonia.

It's probably the number one reason we want to do this series on sustainability. Our group alone is probably a huge contributor alone since we are getting constant product from companies [nervous laugh].

With that being said, running is a privilege. I've come to love it. Being able to run and get out there, there are certainly benefits and positives that come with that. We're not trying to tell people to be different, we just want to evolve the model to enable people to continue to be as they are. You are not the problem because you want to run loads and enjoy running. The problem is in the way that the model of footwear has been created. We need to change the model, and we will.

I think what excites me is the buy-in from our customers, our athletes, from everyone that has touched the brand. They really understand the need for Hylo in the market. The product has been really well-received and continues to get great reviews on our website and also clear and engaged feedback. Our customers are telling us how it's improved and we're getting community buy-in to take the brand to the next level. That's encouraging to me; I haven't been in shoes, this is my first time running a shoe company and hopefully my last. The response has been epic and we've had so much support from different people and I think the main thing is that most nearly everyone who touches the brand understand we are on a journey and they really willing to support us and get behind us because they believe in the mission. That's the most single most powerful thing that we have is kind of building our community. We really want to see change in footwear and we really want help to get there. Because it's not just us getting there, it's everybody who supports us by buying a shoe and giving us hard earned money to improve and change the way things are done.

How did the name come about?

It was a labor of love. Hylo comes from the name for plant, Hylotelephium, which is a mouthful. It's a perennial succulent; so it's a plant that grows all-year round. In Greek Hylo means "matter." We thought it was an interesting synergy, that there is a plant that lives forever that also means life ever-lasting and then you have Hylo in Greek which means "matter." What is a brand of the future look like? It's one that matters and has a purpose.

Athletes since beginning of time have been the pinnacle of human achievement. As a sports brand, to be able to tell those stories in a slightly different way, and to have the feedback of athletes on the products who have high expectations. To have the ability to associate to those type of people gives us a lot of credibility, ability to improve. That's been great. What's been most exciting about it, I thought to myself at the beginning of the journey, "am I the only athlete who things like this?" I realized after speaking to others that there is a huge shift happening in the sports community to sustainability as well. People wanting to understand more and do better. The support we've had from that world has been phenomenal.

For short term, we want to continue to improve the product for the customer and really every time they support us and comeback they can feel the improvements. The positive changes from both environment and performance perspective. I want to keep refining our brand and what we stand for and how we communicate that. The world of sustainability can be quite cluttered. We need to continue to educate people without being patronizing. Being able to stand on our legs about the topic. From an impact point of view, we want to be a brand that drives meaningful, objective, quantifiable impact in our industry. It's all well and good giving big promises around goals and big targets. But every product we make and everything we do needs impact to our goal.

Conclusion

We would like to thank Michael for taking the

time to speak with us about Hylo! To learn more about the brand and to find their Run 2, visit the site here. We are excited to forge on with the series with a new brand out of California in our next edition of the sustainability project. Stay tuned!

If you would like to talk with the team about the Sustainability Project, email Bach Pham at doctorsofrunning@gmail.com.

Editor's Note

This discussion was not

a sponsored piece with Hylo. We appreciate Michael and his team at Hylo for their time and

willingness to talk about product and challenges with us.

Past Feature

Volume 1: Reebok's Push towards a {Ree]newable Future